Basic Info.

Model NO.

HS-001

Usage

Heavy Duty Trucks, Car, Tractors, Farm Machinery

Working Mode

Spring

Working State

Arc Spring

Voltage

Arc Spring

Electromagnetic Clutch

Arc Spring

Wire Range

From Min 0.1mm(0.004inch) to Max 12mm(0.48inch)

Material Standard

DIN17223, 2fd Sicr, 55sicr, Fd Sicr, Td Sicr

Steel Wireoil Tempred Quenched High Carb

Oil Tempred Quenched High Carbon Spring Steel Wire

Application

Dual Mass Flywheel Torque Converter Arc Spring Clu

Transport Package

Carton

Specification

1.0-9.0MM

Trademark

TEMB OEM

Origin

China

HS Code

73202090

Production Capacity

100000000

Product Description

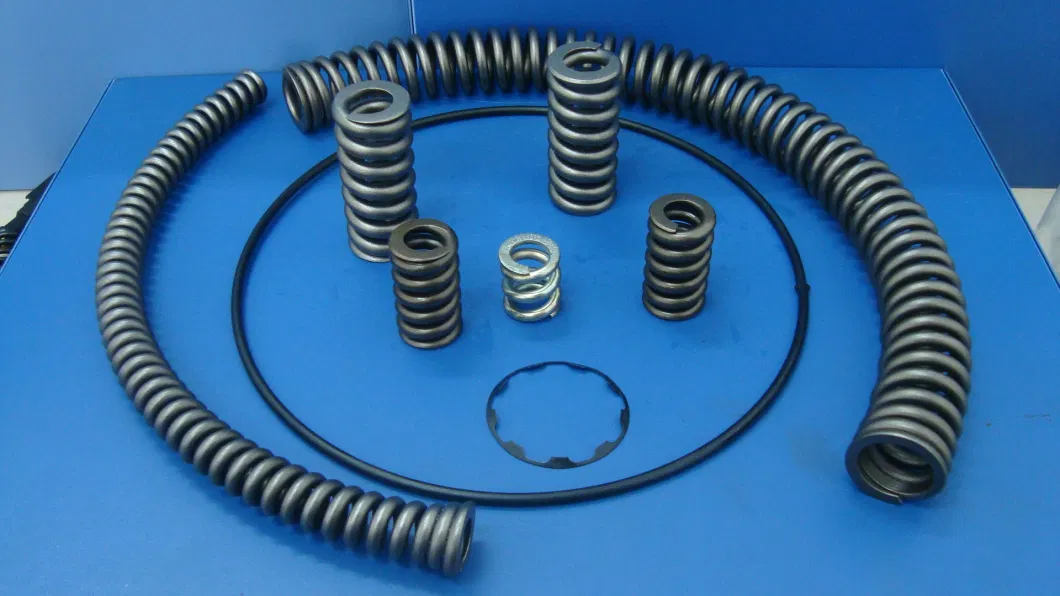

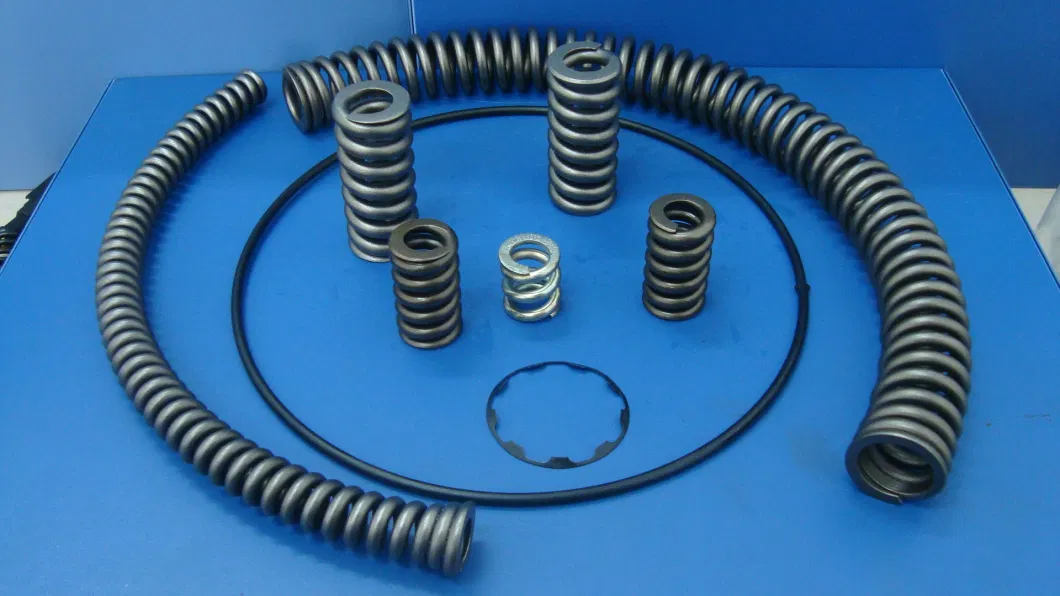

The arc spring (also known as - bow spring, curved spring, circular spring or "banana" spring) is a special form of coil spring which was originally developed for use in the dual-mass flywheel of internal combustion engine drive trains. The term "arc spring" is used to describe pre-curved or arc-shaped helical compression springs. They have an arc-shaped coil axis.

Function

Like other technical springs, arc springs are based on the fundamental principle of storing mechanical work in the form of potential energy and the ability to release this energy again. The force is applied through the ends of the spring. A torque can be transmitted around an axis via the force directed along this helical axis and the lever arm to the system center point. The wire of the arc spring is mainly subjected to torsional stress.

Support

Arc spring with sliding shell.

Representation of the friction hysteresis of a single-stage arc spring supported by a sliding shell in a torque-angle characteristic curve.

An arc spring requires suitable support to transmit torque. The support is usually provided from the outside in the form of an arcuate channel (sliding shell) or radially shaped support plates. This prevents buckling of the arc spring. Another result of this support is a hysteresis between the loading and unloading curves in the characteristic curve. This results from the friction of the spring on the radial support and is an intended effect to achieve damping in the system.

Arc spring systems

As with compression springs, spring systems can also be used for arc springs. The main designs are series and parallel connection. With these, single-stage or multi-stage spring characteristics can be achieved. In order to make optimum use of the available space, systems consisting of inner and outer arc springs are often used.

Representation of the friction hysteresis of a two-stage arc spring supported by a sliding shell in a torque-angle characteristic curve.

In addition, the spring characteristic can be influenced by other parameters such as the cross-sectional geometry of the wire, the coil diameter or the number of coils.

Applications

Schematic representation of bow springs in a dual mass flywheel.

The arc spring is suitable for static and quasi-static as well as dynamic applications. Examples include:

Dynamic applications:

Dual mass flywheel

Torque converter

Arc spring clutch

Belt tensioners, pulley decouplers

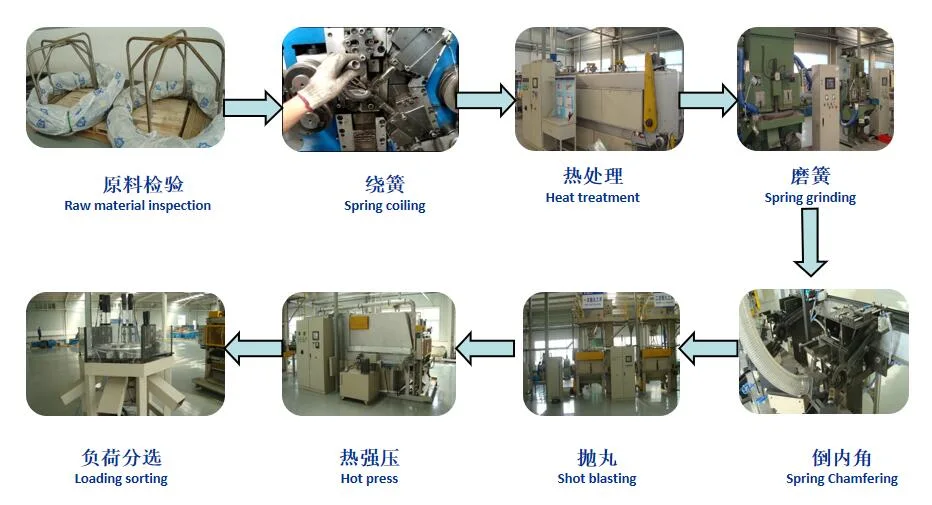

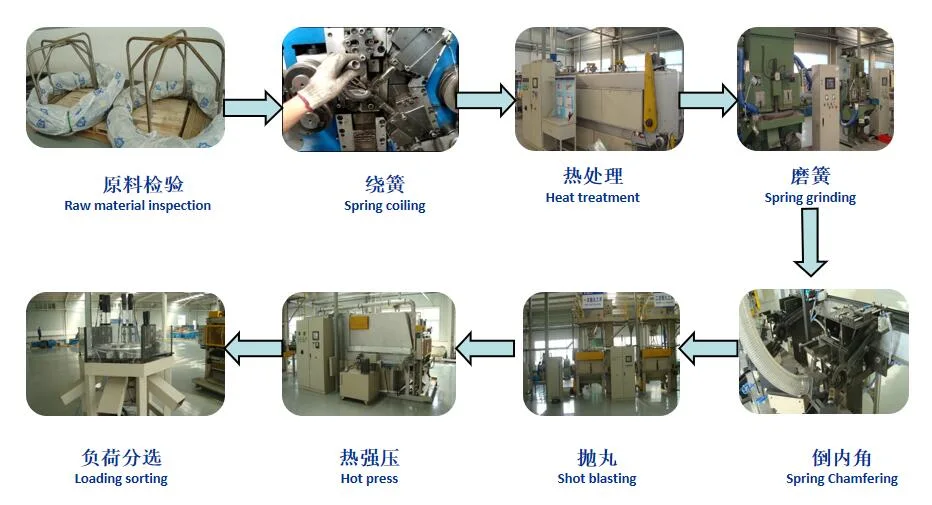

TEMB has been specialized in spring for 20 years. With 15 computer coiling machines, 13 heat-treatment furnaces, 16 spring grinding machines, 6 chamfering machines, 8 setting machines, 5 shot-blasting machines, 1 full automatic load sorting machine, 8 fatigue machines, 6 tension and compression testing machines, TEMB can produce all kinds of springs with diameter 0.2~12.0mm, annual capacity 80 million pcs.

We have established long and friendly cooperation relationship with high level steel manufacturers at home and abroad, ensuring the reliable raw material quality, such as SUMITOMO and Suzuki Garphyttan from Japan, KISWIRE from Korea, and SINOSTEEL from China.

Why Choose Us

1.OE supplier, Reliable quality.

2.OEM, buyer design, buyer label services provided.

3.Exclusive and unique solution can be provide to our customer by our welltrained and professional engineers and staffs.

4.we have the certification of IATF16949, ISO14001.

5.Special discount and protection of sales area provided to our distributor.

6.Timely delivery

7.Good after-sale service

8.Small MOQ is acceptable

Function

Like other technical springs, arc springs are based on the fundamental principle of storing mechanical work in the form of potential energy and the ability to release this energy again. The force is applied through the ends of the spring. A torque can be transmitted around an axis via the force directed along this helical axis and the lever arm to the system center point. The wire of the arc spring is mainly subjected to torsional stress.

Support

Arc spring with sliding shell.

Representation of the friction hysteresis of a single-stage arc spring supported by a sliding shell in a torque-angle characteristic curve.

An arc spring requires suitable support to transmit torque. The support is usually provided from the outside in the form of an arcuate channel (sliding shell) or radially shaped support plates. This prevents buckling of the arc spring. Another result of this support is a hysteresis between the loading and unloading curves in the characteristic curve. This results from the friction of the spring on the radial support and is an intended effect to achieve damping in the system.

Arc spring systems

As with compression springs, spring systems can also be used for arc springs. The main designs are series and parallel connection. With these, single-stage or multi-stage spring characteristics can be achieved. In order to make optimum use of the available space, systems consisting of inner and outer arc springs are often used.

Representation of the friction hysteresis of a two-stage arc spring supported by a sliding shell in a torque-angle characteristic curve.

In addition, the spring characteristic can be influenced by other parameters such as the cross-sectional geometry of the wire, the coil diameter or the number of coils.

Applications

Schematic representation of bow springs in a dual mass flywheel.

The arc spring is suitable for static and quasi-static as well as dynamic applications. Examples include:

Dynamic applications:

Dual mass flywheel

Torque converter

Arc spring clutch

Belt tensioners, pulley decouplers

| Material | Carbon Steel, Stainless Steel, Alloy Steel, Cold Rolled Steel, Music Wire, Copper Wire, Oil Tempred Quenched High Carbon Spring Steel Wire VDSiCr CrSi TDSiCr FDSiCr 55SiCr. |

| Wire Diameter | 0.1mm-10mm |

| Surface treatment | Zinc, Chrome, Nickel, Silver, Gold, Tin, Powder coating, Oxide black, Phosphorization, Darcolo, etc |

| Application | Dual mass flywheel; Torque converter; Arc Spring Clutch; Belt Tensioners; Pulley Decouplers |

| Certification | IATF 16949; ISO14001 |

| Package | Lnner plastic bag, outer carton, can be customized according to customer requirements |

| Production Time | 30 Days, According to customer order quantity |

| Payment Terms | Pay the balance 30%, 70% before delivery, can be adjusted according to the situation |

| Origin | China, Shandong |

TEMB has been specialized in spring for 20 years. With 15 computer coiling machines, 13 heat-treatment furnaces, 16 spring grinding machines, 6 chamfering machines, 8 setting machines, 5 shot-blasting machines, 1 full automatic load sorting machine, 8 fatigue machines, 6 tension and compression testing machines, TEMB can produce all kinds of springs with diameter 0.2~12.0mm, annual capacity 80 million pcs.

We have established long and friendly cooperation relationship with high level steel manufacturers at home and abroad, ensuring the reliable raw material quality, such as SUMITOMO and Suzuki Garphyttan from Japan, KISWIRE from Korea, and SINOSTEEL from China.

Why Choose Us

1.OE supplier, Reliable quality.

2.OEM, buyer design, buyer label services provided.

3.Exclusive and unique solution can be provide to our customer by our welltrained and professional engineers and staffs.

4.we have the certification of IATF16949, ISO14001.

5.Special discount and protection of sales area provided to our distributor.

6.Timely delivery

7.Good after-sale service

8.Small MOQ is acceptable